Cement Plant Carbon Txhuam D172

Cov lus piav qhia ntxaws

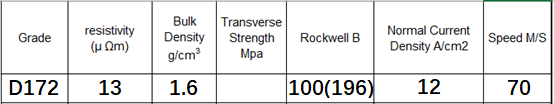

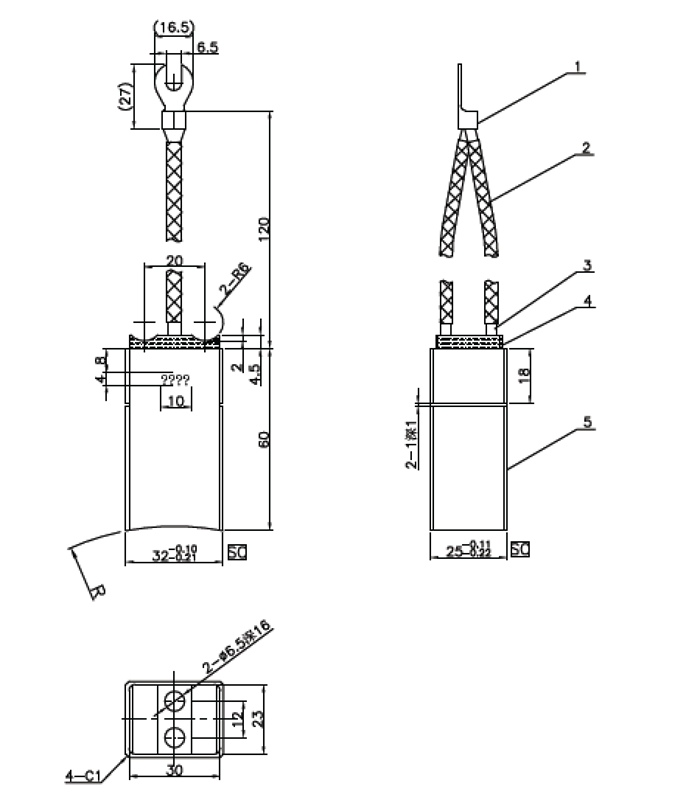

| Carbon txhuam tus lej | Hom | A | B | C | D | R |

| MDT11-M250320-016-19 | J201 | 25 | 32 | 60 | 6.5 | R140 |

| MDT11-M250320-016-20 | J201 | 25 | 32 | 60 | 6.5 | R177.5 |

| MDT11-M250320-016-21 | J204 | 25 | 32 | 60 | 6.5 | R140 |

| MDT11-M250320-016-22 | J204 | 25 | 32 | 60 | 6.5 | R177.5 |

| MDT11-M250320-016-23 | J164 | 25 | 32 | 60 | 6.5 | R140 |

| MDT11-M250320-016-24 | J164 | 25 | 32 | 60 | 6.5 | R177.5 |

Txhuam hom

Peb cov pa roj carbon txhuam yog ua raws li txhua qhov kev xav tau

Cov pa roj carbon txhuam yuav tsum tiv taus qhov ceev tam sim no thiab hloov tam sim no mus rau cov khoom sib hloov. Carbon txhuam rau ncej hauv av yuav tsum muaj kev nyab xeeb dissipate voltages ntawm qhov qis tshaj tam sim no los ntawm rotating shafts. Tsawg hluav taws xob poob thiab kev sib txhuam tsis zoo nrog rau cov khoom siv qis qis yog qhov tseem ceeb rau kev sib cuag zawv zawg. Cov ntaub ntawv carbon ua tau raws li tag nrho cov kev xav tau tshwj xeeb zoo, ua rau nws nyiam cov khoom siv rau cov ntaub ntawv ntsig txog kev xa mus tam sim no hauv cov tshuab hluav taws xob.

Cia peb cov kws tshaj lij pab koj xaiv cov khoom tsim nyog thiab tsim cov txhuam hniav zoo tshaj plaws.

Cov kev xav tau ntawm peb cov khoom yog manifold: Ntawm ib sab, lub neej ua haujlwm ntev, kev ua haujlwm ntawm lub cev yuav tsum siab npaum li qhov ua tau thiab, nyob rau hauv cov ntaub ntawv ntawm cov khoom siv hauv tsev, lub cev muaj zog khiav yuav tsum tau txhim kho. Ntxiv rau qhov no yog kev ua haujlwm txhim khu kev qha yam tsis muaj kev puas tsuaj rau lub commutator lossis lub nplhaib plam, kev nyab xeeb siab tshaj plaws hauv kev ua raws li cov qauv kev cuam tshuam kev cuam tshuam thiab, qhov kawg tab sis tsis tsawg kawg, tus nqi sib piv zoo.

Peb daws qhov yuav tsum tau muab tso rau ntawm peb nrog ntau yam khoom siv, txheej txheem tsim khoom hauv lub xeev thiab kev paub zoo. Piv txwv li, peb tuaj yeem tsim koj cov khoom los ntawm impregnation los yog geometry adaptation nyob rau hauv xws li ib txoj kev uas lub xov tooj cua cuam tshuam tus cwj pwm thiab cov hluav taws xob thiab tribological zog yog optimized. Kev ua haujlwm ntxiv xws li damping ntsiab, plua plav raws thiab tsis siv neeg lub teeb liab thiab kaw cov khoom siv kuj tseem ua tau. Txawm tias muaj qhov ceev tam sim no, kev vibrations, plua plav tiam, kev kub ceev lossis huab cua tsis zoo, koj tuaj yeem tso siab rau qhov kev ua tau zoo ntawm peb cov khoom. Dab tsi ntxiv, peb tuaj yeem muab lawv rau koj raws li cov khoom sib dhos ua tiav - uas ua kom zoo dua koj lub rooj sib txoos raws sijhawm thiab tus nqi. Vim hais tias nyob rau hauv tas li ntawd mus rau optimization ntawm cov khoom, peb kuj tseem nco ntsoov lub qhov muag ntawm tus nqi-zoo rau koj: Peb muaj peev xwm tsim tau ntau ntawm peb cov pa roj carbon txhuam hniav siv cov txheej txheem tshwj xeeb uas haum rau pressed-rau-loj, uas yuav tsum tsis muaj txhua yam ua.